Invest Sensibly: Resource the Perfect Dirt Screen for Sale for Your Dirt Handling Demands

Invest Sensibly: Resource the Perfect Dirt Screen for Sale for Your Dirt Handling Demands

Blog Article

Upgrade Your Recycling Arrangement: Discover the Conveniences of Modern Dust Screens

This is where modern dust screens come right into play, reinventing the recycling industry with their innovative technology and various advantages. By applying these cutting-edge displays, reusing centers can expect boosted sorting effectiveness, reduced contamination levels, improved recyclable high quality, lowered maintenance and downtime, and substantial cost financial savings. Interested to know even more regarding exactly how these contemporary dust displays can transform your recycling setup?

Improved Arranging Efficiency

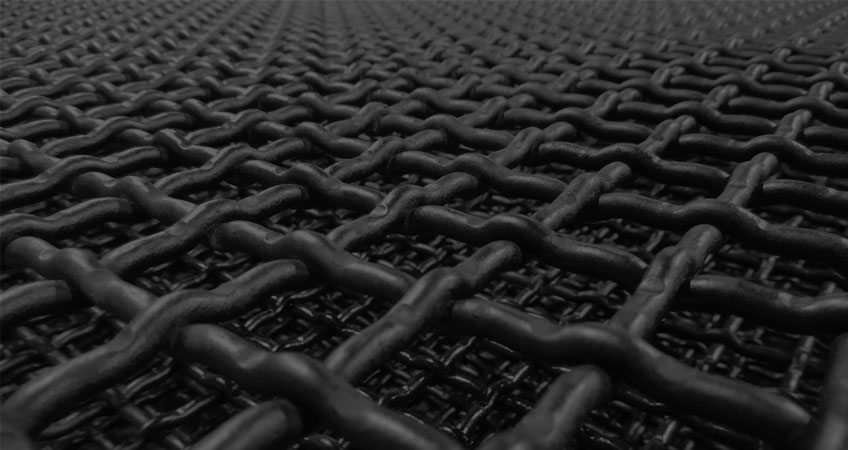

Improved sorting efficiency is a vital facet in the growth and implementation of modern dirt displays, ensuring optimal efficiency and productivity. With advancements in technology, dust screens have evolved to include sophisticated sorting mechanisms that streamline the splitting up process. By successfully separating different kinds of products, such as rocks, particles, and natural matter, these displays boost the total performance of reusing and waste administration operations.

Among the vital functions adding to improved sorting performance is the implementation of sophisticated sensor systems. These sensors can detecting and classifying products based on their dimension, density, and structure. By precisely determining various kinds of materials, the dust displays can effectively divert them to their particular handling streams, reducing hand-operated arranging efforts and lessening the risk of cross-contamination.

Additionally, modern-day dirt screens are equipped with smart algorithms and software that allow real-time information evaluation. This allows drivers to keep an eye on and change the arranging process for ideal performance. By evaluating data on product structure, circulation rates, and display performance, operators can make informed decisions to make best use of efficiency and lessen downtime.

Moreover, the integration of automated sorting devices, such as conveyor belts and pneumatically-driven systems, better boosts the sorting effectiveness of modern-day dust displays. These systems assist in the constant motion of products, making sure a steady circulation for arranging and decreasing still time.

Reduced Contamination Degrees

Minimizing contamination levels is an important purpose in the layout and application of modern-day dust screens, ensuring the honesty and quality of separated materials. Contamination refers to the presence of unwanted materials, such as debris, dirt, or foreign things, that can adversely influence the reusing procedure. By efficiently lowering contamination degrees, modern dust displays contribute to the production of cleaner and purer recycled products.

Additionally, decreasing contamination degrees aids to keep the effectiveness and reliability of reusing procedures. Impurities can create devices damage, bring about boosted maintenance costs and manufacturing downtime. With modern-day dust screens in place, the threat of equipment failure and break downs as a result of contamination is lessened, ensuring smoother and undisturbed recycling processes.

Additionally, decreasing contamination levels is essential for meeting regulative demands and ecological criteria. Several nations have rigorous standards pertaining to the maximum permitted levels of contaminants in recycled products. By utilizing modern dirt displays, reusing facilities can adhere to these laws, preventing charges and preserving a positive ecological track record.

Boosted Recyclable Quality

By ensuring the removal of unwanted substances, dirt displays add to the manufacturing of higher-quality recyclable materials. In the recycling process, dirt screens play a crucial duty in improving the high quality of recyclables. These displays properly separate undesirable debris, such as dust, rocks, and other contaminants, from the recyclable products. This separation makes sure that only clean and pure products are processed better, causing a higher-quality final product.

Using modern-day dirt displays has substantially improved the quality of recyclable products. These screens site are created with sophisticated technologies that can effectively get rid of even the smallest bits of dust or pollutants (dirt screen for sale). As an outcome, the last recycled item is of exceptional quality, fulfilling the stringent requirements set by suppliers and customers

The boosted recyclable quality achieved with the use of dust screens advantages various markets. For manufacturers, higher-quality recyclable products indicate an even more consistent and trustworthy resource of raw materials.

Consumers additionally benefit from the improved recyclable top quality. With cleaner and purer products, items made from recycled materials are more trustworthy and resilient. This increases customer confidence in acquiring recycled products, even more driving the need for lasting and eco-friendly products.

Lowered Maintenance and Downtime

One of the noteworthy advantages of making use of modern dirt screens is the lowered need for upkeep and the decrease in downtime. Conventional reusing setups commonly need regular maintenance to eliminate clogs, tidy displays, and address various other functional concerns. This not just results in increased labor expenses yet also causes substantial downtime, decreasing overall efficiency.

Modern dust screens, however, are made with innovative technologies that minimize the need for regular maintenance. These screens are furnished with self-cleaning mechanisms that instantly remove debris and protect against obstructing, thus decreasing the requirement for hand-operated treatment. By eliminating the requirement for frequent maintenance, reusing facilities can conserve time and resources, allowing them to concentrate on their core procedures.

In addition, the decrease in downtime supplied by modern dirt displays has a straight effect on productivity. Contemporary dirt screens are engineered to be extra efficient and dependable, reducing the occurrence of operational interruptions.

Cost Financial Savings and Ecological Effect

Using modern-day dust displays not web only provides price savings but likewise has a favorable ecological effect. These innovative screens are designed to successfully separate dirt and particles from recyclable materials, guaranteeing this content a higher top quality final product. By effectively getting rid of pollutants, contemporary dirt screens help minimize the amount of waste that winds up in garbage dumps or burners, thus reducing the ecological burden.

One considerable cost-saving facet of modern-day dirt displays is their capacity to enhance the general efficiency of recycling procedures. By eliminating dust and particles, these screens avoid blocking and damage to recycling devices, lowering the demand for pricey repair work and downtime. Furthermore, the cleaner and purer recyclable products gotten via making use of dirt displays command higher rates in the marketplace, resulting in raised income for reusing facilities.

Furthermore, the favorable ecological impact of modern-day dust displays extends beyond waste decrease. By separating dirt and particles from recyclable materials, these displays allow more effective reusing processes, preserving energy and minimizing greenhouse gas discharges related to conventional waste monitoring methods. This not just aids combat climate modification however additionally adds to the conservation of all-natural resources.

Verdict

To conclude, upgrading recycling arrangements with modern dirt displays supplies various advantages. These include enhanced arranging efficiency, decreased contamination levels, boosted recyclable top quality, minimized maintenance and downtime, in addition to cost savings and positive environmental impact. By implementing these improvements, recycling facilities can optimize their operations and contribute to a much more sustainable future.

Lessening contamination degrees is a vital purpose in the style and implementation of modern-day dirt screens, making certain the honesty and quality of separated materials. By successfully reducing contamination levels, modern dust displays contribute to the production of cleaner and purer recycled products.

The usage of modern dust displays has substantially enhanced the top quality of recyclable products. Furthermore, the cleaner and purer recyclable materials obtained through the usage of dust displays regulate greater costs in the market, leading to raised earnings for recycling facilities.

By dividing dirt and debris from recyclable products, these screens enable more effective reusing procedures, saving energy and minimizing greenhouse gas exhausts associated with standard waste management approaches.

Report this page